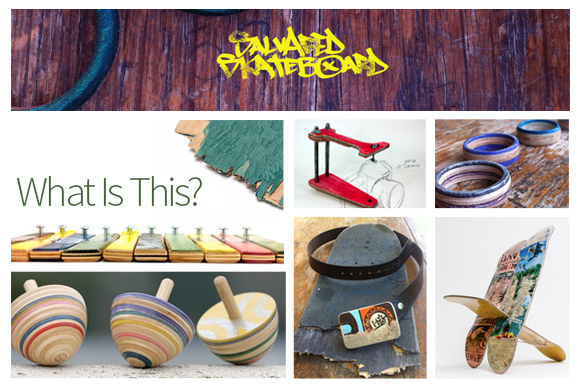

It is important to us here at the Roarockit Skateboard Company to keep up with trends in the skateboard industry – especially anything to do with supporting local builders and artists! We recently came across a unique start up called Salvaged Skateboard Shop that is trying to create an online marketplace that focuses on independent builders and crafters who are working with skateboards as their medium.

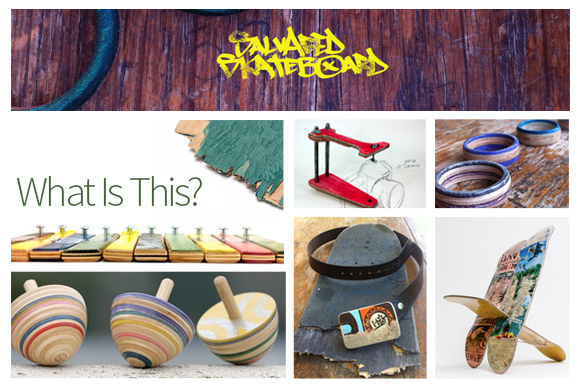

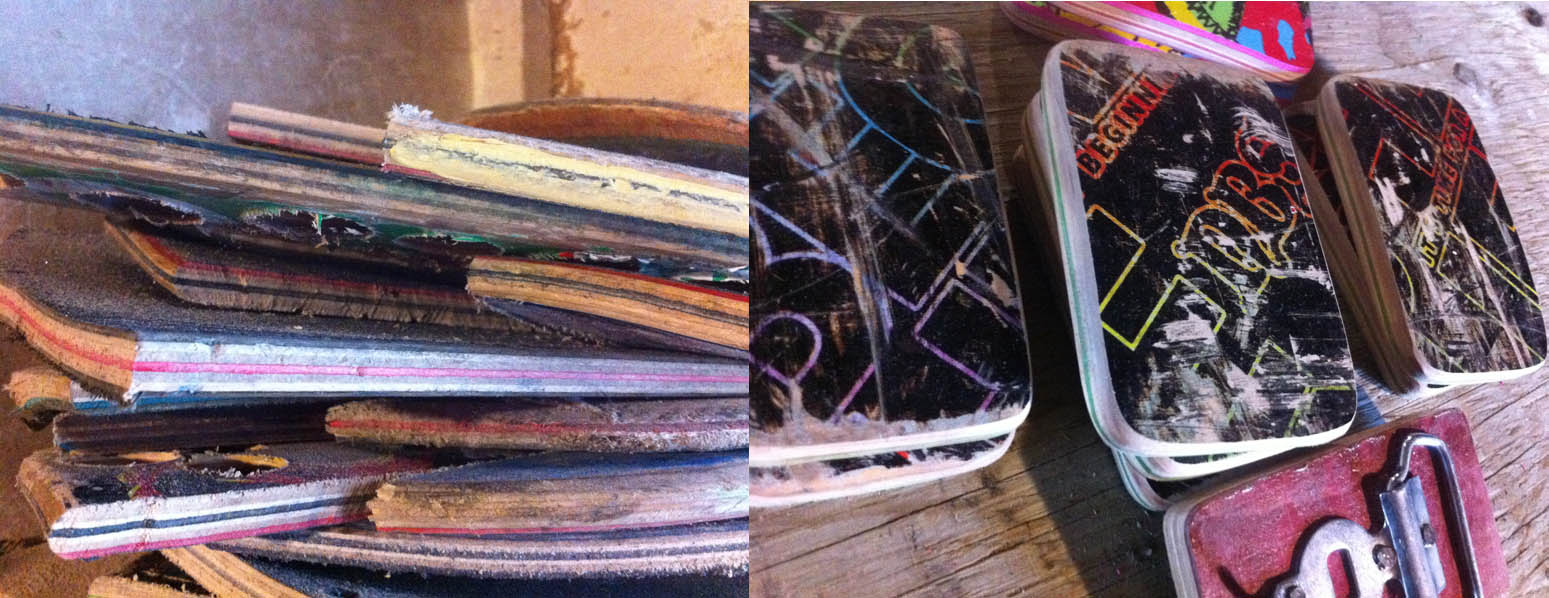

The man behind Salvaged Skateboard, Chris Anderson, got his start making projects out of recycled skateboard decks after travelling with his wife and coming across a shop in Nova Scotia that sold rings made out of old decks. He went home, tried making some himself, and eventually started expanding his production of custom skateboard accessories.

As his hobby grew, he soon realized that he was not the only person making beautiful projects out of reclaimed skateboard materials. This (combined with his background as a web and app developer) led to the idea of an online marketplace where builders could display and sell their work in a focused community.

We spoke with Chris to hear more about his plans for the site and the crowdfunding campaign he has started to help launch the marketplace.

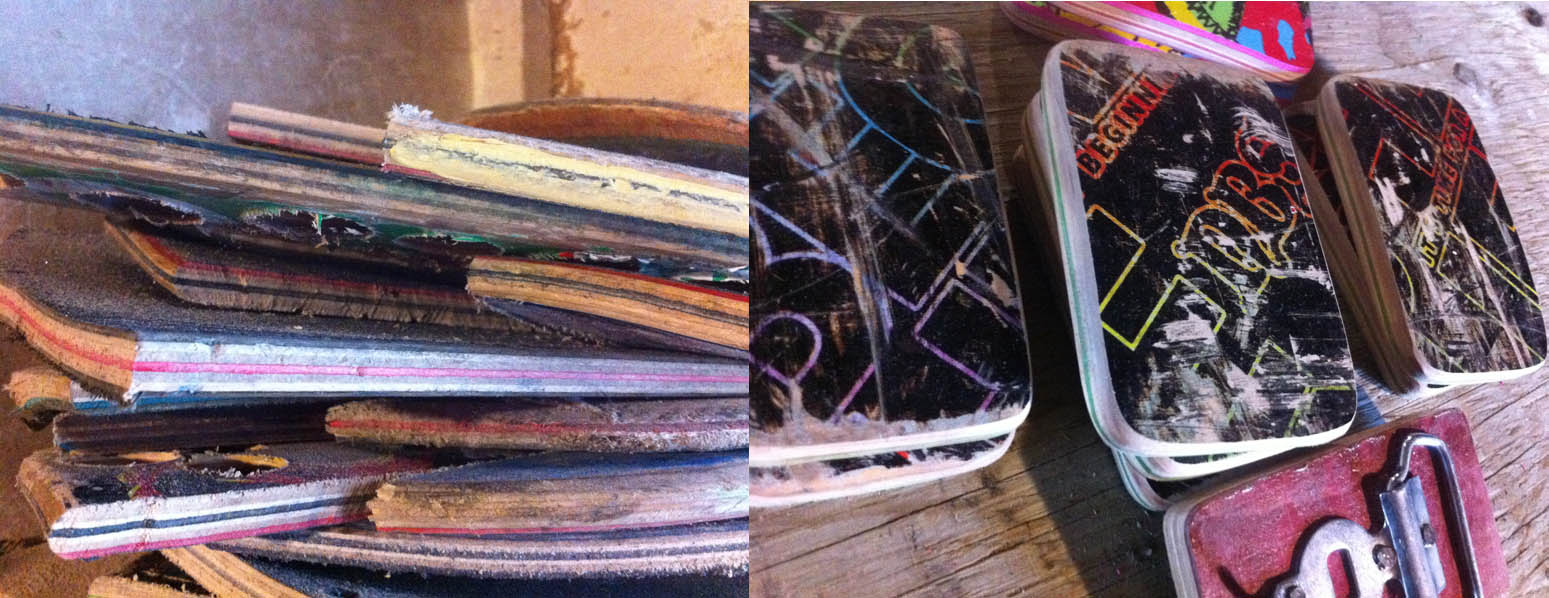

Where do you get recycled skateboard decks for your own projects?

I get my boards from local skate shops here in Ottawa. They have a program where you can bring in your old boards and they will fix them up to give back out to the under privileged in the community. Some of boards are too far gone and they give them to me or to other local artists.

What benefits do you think Salvaged Skateboards can offer to an independent builder/artisan?

Salvaged Skateboard is about creating a focused online marketplace for those buying and selling unique, functional pieces of everyday art from recycled skateboard decks - such as handcrafted jewelry, accessories, furniture, eyewear, and the list goes on. This will also be an environment for independent skateboard deck builders to sell their custom decks and a great way for these people to find each other on a local level.

What do you mean by a focused marketplace? Like Etsy, eBay etc.?

Basically one of the winning strategies behind a large online marketplace is that it lets everyone setup, share and promote their own unique shops. Not one shop selling many products, but many unique stores selling their own unique products. All under the same umbrella, collecting all the metadata from all the different storefronts combined.

Why then might this be a better option than paying for your own 'out-of-the-box' style ecommerce website?

The first major advantage with this marketplace is that it would be large enough and focused enough to get out in front of every search engines category related to skateboarding. The second major advantage over your own ‘out-of-the-box’ ecommerce website is word-of-mouth and the community. Instead of trying to sell your own products to everyone in your social circle, there would be hundreds of people telling all of their social circles to go checkout Salvaged Skateboard.

How have you been received by the skate community so far?

It’s been extremely positive so far! There has been a lot of enthusiasm, support and some great feedback. I can take criticism and am always looking to improve the idea to make it a great hub for everyone in the skate community.

What other communities do you look to engage with the site?

I would like to engage with artists, designers and board builders of all kinds because there are endless amounts of possibilities for creation with salvaged skateboards. We also need to engage skaters that want to donate their boards, as this is a very important part of the artistic process, and the general public that are interested in promoting local artists and want to buy unique one of a kind items.

Make sure to check out the Salvaged Skateboard Indiegogo campaign!

We think this is a great project, and any help spreading awareness to get this idea off the ground will go along way towards making it a reality.

Thursday, June 26, 2014 at 11:48AM

Thursday, June 26, 2014 at 11:48AM  Post a Comment →

Post a Comment →  DIY,

DIY,  hand pump,

hand pump,  how to,

how to,  longboard. roarockit,

longboard. roarockit,  skateboard,

skateboard,  thin air press

thin air press