Brand New BIRCH Veneers Pt.3

Conclusion

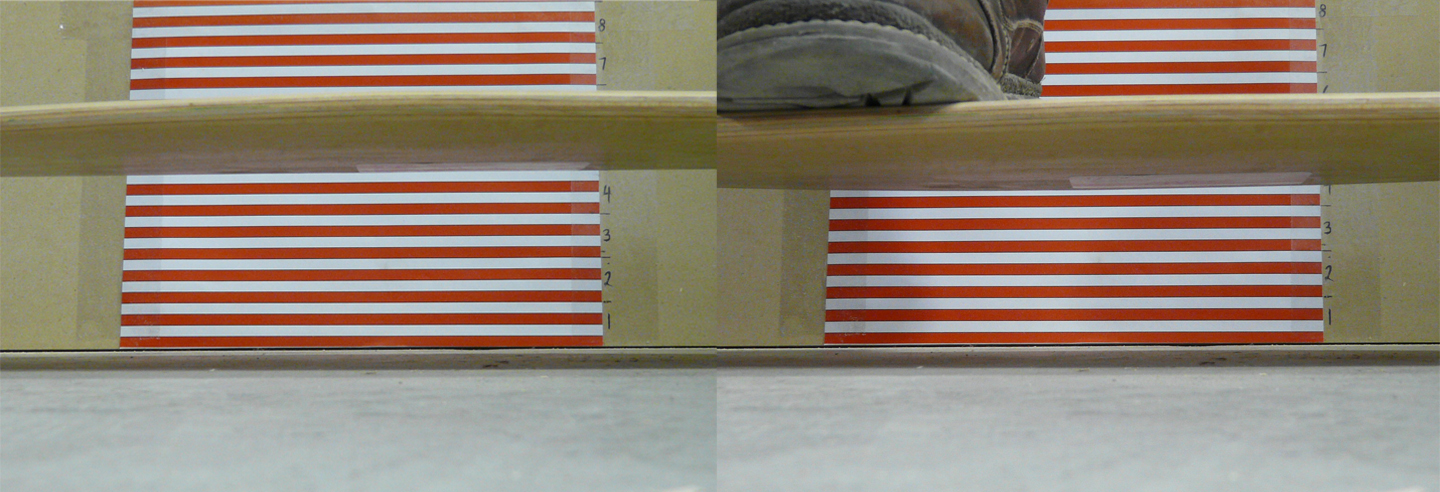

From a board builder and riders perspective, we are quite pleased with the results of the 1/16” Solid Birch veneers. We found them very easy to work with, and the results were a nice contrast to our standard Maple veneers. Both are very strong/durable, and access to both now allows builders to further customize their rides. There is also the possibility of combining both materials on the same board to help create a unique weight and flex. The fact that Roarockit offers both at the same price allows builders to mix and match material with ease (contact us directly to order your own customized mix of veneers) .

Compared to other common board building materials on the market, our Birch veneers compare nicely to the popular bamboo/foam core alternatives. Especially for 'dancers' and boards meant to have a substantial amount of flex.

The durable, flexible and lightweight properties of the Birch are what lead us to making the Bamboo comparison in particular. It is also worth noting - for our North American builders who import bamboo from overseas, the fact that we have found a local source for our Birch veneers, helps reduce our carbon footprint and keeps cost down for everyone.

Through our research and testing, we concluded that the 1/16” Solid Birch was the most dynamic new material that wasn't readily available to board builders. It is no secret that the Birch Plywood found in most local lumber and hardware stores is not an ideal building material for skateboards. However, we chose to test this material because it is often used by beginners due to it's widespread availability.

Roarockit welcomes anyone who has tried our new Solid Birch veneers to send us their feedback and experiences working with the material. Also, if anyone feels like further breaking down the science behind some of our findings, any and all data or suggestions would be greatly appreciated... We may look great in our lab coats – but in reality, are much better skaters/woodworkers than we are scientists!

We would like to thank you all for your continued support of the Roarockit Skateboard Company. It brings us great joy when we see our hard work and dedication to classrooms/independent builders, pay off with positive comments and success stories from around the world.

Happy building!

Friday, June 8, 2012 at 2:42PM

Friday, June 8, 2012 at 2:42PM  Post a Comment →

Post a Comment →